|

High Tech Driveshafts By Bill "BillaVista" Ansell |

|

The story begins here...the old beaten-down 350 SBC was well past retirement age. Probably not capable of more than 200HP - it was time to go. | ||||||||||||

|

In its place went a fire-breathing 525HP Gen IV LS2 from Turn Key Engine Supply. | ||||||||||||

Of course, with big power can come big problems if the rest of the drivetrain isn't up to snuff. As you can see from the above - it's coupled to a good-old TH400 tranny and behind that the venerable Atlas-4SP. The next thing in the path of all those ponies is the driveshafts. The size and strength requirements for driveshafts are primarily related to six factors:

These factors are also cumulative - each multiples the others. |

|||||||||||||

|

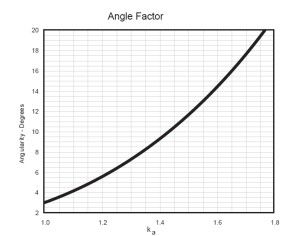

Here's a graphical example of the effect of operating angle. The "angle factor", labelled Ka, and read along the bottom of the graph, may be thought of as "the number of times by which torque capacity of the shaft is reduced based on operating angle". As you can see, there's a pretty dramatic effect - and this graph (sourced from Spicer industrial data) doesn't even go anywhere near as high as my application will in terms of angularity. |

||||||||||||

|

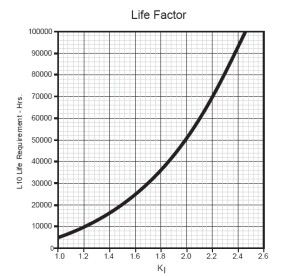

Here's an example of the effect of "life factor", or the number of hours one expects the driveshaft to last. Obviously, the longer you need the shaft to last for a given input power, the larger and stronger it will need to be. Looked at from the other view, we can say that the more maintenance one is prepared to do, the better shape the driveshaft will be in, and the greater its load-carrying capacity will be. |

||||||||||||

| So, when we add all that up, we quickly discover I've inadvertently created the worst possible set of circumstances in which a driveshaft can operate: big power, heavy weight, high angles, high speed, and high shock loading. The only thing I could possibly compromise on is conducting more frequent inspection, lubrication, and maintenance. Other than that - it's going to take some kinda driveshafts to keep my rig together. | |||||||||||||

|

Not only that, but creating a "high performance" vehicle also places a lot of challenging "packaging" requirements on the builder. Essentially, you want to keep everything packaged as tightly as possible to keep vehicle profile down and maximize suspension travel while also keeping C of G low and visibility high. Doing this, with my original front driveshaft, led to a snag as you can see at left. |

||||||||||||

|

When the front axle is raised to full bump, the driveshaft tube contacts the starter mounting bolt. | ||||||||||||

|

Even at ride height there wasn't much clearance. | ||||||||||||

|

And there wasn't much room for the TH400 automatic transmission's vacuum modulator hose either. | ||||||||||||

Great - so now I not only needed shafts that could handle high power, heavy weight, high speed and shock loads - but I also needed some kind of special high-clearance front shaft that wouldn't compromise strength. Oh well, I knew that if anyone could help it would be Jess at High Angle Driveline - and he didn't disappoint. As it turned out - he was working on two brand-new products that would be perfect for my demanding needs. Here's a look at the:

and the

Tight-Clearance Chromoly Trophy-Truck Spline Front Driveshaft |

|||||||||||||

|

This is the Tight-Clearance driveshaft using the chromoly Trophy-Truck Spline - designed for extreme travel and for clearing tight spots without any loss of strength - just like the one near my starter. | ||||||||||||

|

At the transfer case end, it features the popular HAD 1350 1-ton CV joint (double-cardan). This custom CV joint features 1350-series greaseable U-joints and is capable of running at angles up to 32°. |

||||||||||||

|

Close-up of the 1350 1-ton CV. | ||||||||||||

|

The 1350 CV is designed to be used in conjunction with High Angle Driveline's patented 32-spline transfer case output flange. | ||||||||||||

|

High Angle Driveline's 32-spline transfer case output flange. | ||||||||||||

|

Front view of the 32-spline output flange. This custom-machined, 32 spline transfer case output flange is available for New Process (NP) 203 or 205, 32 spline HD fixed yoke conversion kits for the NV 231(e.g. Advance Adapters, JB conversions, Tera Mfg., etc.), Atlas with 32 spline output, and Dana 20 & Dana 300 with Advance Adapters' 32-spline output conversions. |

||||||||||||

|

The main driveshaft tube is 3" OD / .134" wall which is light, stiff, strong, and balances well. Heavier wall tubing is available, but not recommended for high-speed applications as it is hard to balance, and being much heavier robs a lot of horsepower while not being a great deal stronger. Spinning a much heavier driveshaft is also very hard on other drivetrain components including output shafts, bearings, and seals. |

||||||||||||

|

On the transfer case end of the shaft, the Trophy-Truck spline engages two back-to-back 3" spline sleeves, providing a massive total of 6" of spline engagement. This design also provides a huge lube channel, which combined with the grease nipple placement, results in over four times the lubrication capacity of a traditional shaft. This is a great benefit to a shaft that will be run hard and fast in harsh conditions - remember the life factor? |

||||||||||||

|

The Trophy-Truck spline is the key to the unique capabilities of this shaft. It's a 1.5" major diameter heat-treated 4140 chromoly spline that is incredibly strong and yet easily balanced for use up to and above 100mph. Due to the heat-treat it is considerably stronger than similar-sized tube or solid. |

||||||||||||

|

At the axle end is the spline driver system where the spline terminates in another 3" section of spline sleeve that is welded to 3" OD driveshaft tubing. | ||||||||||||

|

Close-up of the spline driver system. This shaft has a 1410-sized U-joint at the axle end to match the 1410 High Angle Driveline custom yoke on my front Dana 60 axle. Note the large weld journals so as to ensure no strength is lost at the weld joints. |

||||||||||||

|

The trick chromoly spline is also protected by a tight-fitting rubber boot that is clamped to the T-case end spline sleeve. This chromoly Trophy-Truck spline is much stronger than a conventional slip yoke, not only because of the superior material and heat treating, but also because of the control it offers over the amount of material around the slip and its construction. |

||||||||||||

|

The whole shaft features HAD's well-known quality construction. Occasionally, under extremely harsh conditions, especially high shock-loads, a traditional cast-iron slip-spline can fracture and fail. The chromoly Trophy-Truck spline is immune to that kind of destruction. |

||||||||||||

|

For those requiring a driveshaft that is strong, smooth, capable of sustained high-speed operation, and provides unsurpassed clearance for tight clearance locations without giving up an ounce of strength - this shaft is the answer. | ||||||||||||

Front Shaft Installed - Shown at Ride Height |

|||||||||||||

|

Here is the Tight-Clearance front driveshaft installed at ride height. | ||||||||||||

|

The gain in clearance is significant, both at the tightest spot - under the starter bolt - as well as... | ||||||||||||

|

... by the transmission vacuum modulator. | ||||||||||||

|

Shot from underneath. | ||||||||||||

|

The Trophy-Truck spline in place. | ||||||||||||

|

Shot from above. | ||||||||||||

Front Shaft Installed - Shown at Full Bump |

|||||||||||||

|

Here is the Tight-Clearance front driveshaft installed with the axle at full bump. | ||||||||||||

|

As you can see, even at full bump the chromo spline affords me plenty of clearance at the starter... | ||||||||||||

|

...and plenty at the tranny vacuum modulator too. | ||||||||||||

|

Shot from lower right. | ||||||||||||

|

Front driveshaft at full bump. | ||||||||||||

42° Durability CV Driveshaft by High Angle Driveline |

|||||||||||||

|

The brand-new 42° Durability CV Driveshaft from High Angle Driveline looks deceptively similar to the original 42° CV driveshaft that HAD pioneered over 5 years ago. | ||||||||||||

|

But make no mistake - this product is something entirely new - and the only one of its kind on the market. | ||||||||||||

|

The original 42° CV was designed to maximize both torque-carrying capacity and angularity - which it did amazingly well - but it lacked prolonged-speed durability - the ability to be run continuously at high speeds such as in racing or road use. The new 42° Durability CV design, shown here, was developed to eliminate this shortcoming. |

||||||||||||

|

Recall that weight is a major factor in determining driveshaft strength requirements. In order to meet demanding GVW requirements and the need for high durability, reliability, and high speed over rough terrain, HAD designed the all-new High Endurance 42° CV Driveshaft. | ||||||||||||

|

The new 42° Durability CV driveshaft features major changes to the ball-and-socket design of the CV joint, as well as a host of other durability features. | ||||||||||||

|

The result is a high-durability, high-endurance, driveshaft that maximizes torque-carrying capacity (well above that of a 1350 CV shaft), high-speed, vibration-free reliability, and... | ||||||||||||

|

...can be run at operating angles unmatched by any other shaft. The result is a unique product that can comfortably be used in the most demanding applications from heavily modified high-power/big-lift trucks, to KOH-style race vehicles. In fact, KOH co-founder Dave Cole runs this shaft as well as the Trophy Truck Spline shaft in his race rig, and 2009 KOH Champ Jason Scherer runs the Trophy Truck Spline shaft. |

||||||||||||

|

It is also a great choice for use in heavily power-modified / highly-lifted full-size trucks like Ford Superduties, Chevy Duramax trucks, and Full-size Dodges - we're talking 8000lb trucks with 1000 ft/lbs torque and 18" of lift. Like most HAD driveshafts, the basic tubing is available in a variety of diameters and wall thickness's to meet your needs. Mine uses 3" OD .134" wall to keep strength and stiffness high without adding excessive power-robbing rotational weight or compromising balanceability. |

||||||||||||

|

My slip-spline features standard 5" travel set at 2" compression and 3" extension. Other combinations are available, depending on your needs. |

||||||||||||

|

The slip-yoke is greasable, as are all the U-joints. | ||||||||||||

|

Slip yokes are available in different sizes to match your axle's yoke. Pictured is my 1410-sized yoke to match the High Angle Driveline 1410 yoke on my trusty 14-Bolt rear axle. |

||||||||||||

|

Note that the design of a shaft that maximizes all three qualities of angularity, torque capacity, and high-speed capability includes pretty rigorous maintenance requirements. In fact, the shaft comes with its own special grease and strict maintenance schedule - every grease fitting requires 5 pumps every 1500 miles. The grease itself is commercially available and the 42° Durability CV driveshaft ships with an initial standard cartridge-style tube. |

||||||||||||

|

The CV is designed to be used in conjunction with High Angle Driveline's custom machined, patented (U.S. Patent USD 462,256,S) 32 spline output flange, same as the Trophy-Truck spline driveshaft. | ||||||||||||

|

The shaft is so strong that, depending on your transfer case, you may need to be concerned with the strength of your transfer case output shaft. As I'm using a 32-spline Atlas, I don't anticipate difficulties, but I also note that Advance Adapters do offer a special 300M chromoly output shaft for the Atlas, should I need it. |

||||||||||||

|

Beautiful! | ||||||||||||

Rear Shaft Installed - Shown at Ride HeightHere is a small gallery showing the rear driveshaft installed at ride height:

|

|||||||||||||

|

|||||||||||||

|

Sources: High Angle Driveline (530) 877-2875 e-mail: forwhlr@saber.net |

|